The E2E DIGITAL TWIN project sets interconnected objectives to create an approach that not only improves the quality and efficiency of production but also modernizes worker training and introduces advanced work methods, significantly impacting both operational and strategic levels.

Project Summary:

The production of high-end natural cork stoppers relies heavily on visual inspections carried out by specialized workers to assess the quality of the stoppers at various stages of the production process. This evaluation impacts both the company’s profitability and customer satisfaction. If high-quality stoppers are mistakenly classified as defective, they are not sold. Conversely, if defective stoppers go undetected, they are sold, compromising customer trust. As a result, the value of the final product is highly dependent on the accuracy and efficiency of this process.

CorkSupply aims to modernize its methods to improve efficiency in quality assessment. This project seeks to disrupt the current inspection and classification process for natural cork stoppers by integrating digital and physical processes through:

- The creation of a Digital Twin for each high-end natural cork stopper produced, as well as for the inspection, quality control, and assembly processes they undergo.

- The use of Machine Learning to analyze and classify cork stoppers and stopper sets, reducing the overlap between adjacent quality classifications—higher (fewer imperfections) and lower (more imperfections).

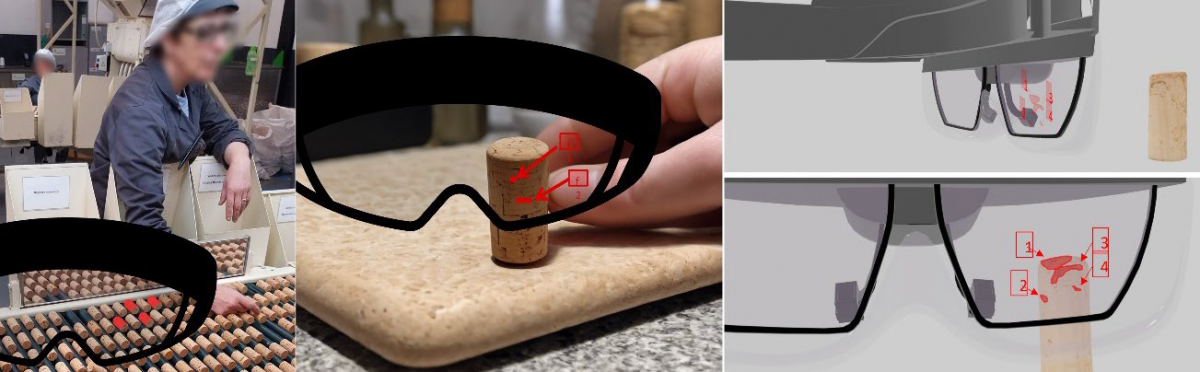

- The use of Augmented Reality devices on the production line to combine workers’ tacit knowledge with data generated by mathematical models in the digital process. This ensures a meticulous, artisan-level quality control process—strategic for CorkSupply’s brand positioning—while improving efficiency and reliability.

- The development of technological strategies to characterize and understand the inspection processes performed by experienced workers and apply this knowledge to interactive multimedia training applications for new workers. This will streamline training processes and engage new generations.

Open positions

Doctoral student positions

Four doctoral student positions available: https://euraxess.ec.europa.eu/jobs/359396 https://euraxess.ec.europa.eu/jobs/359736

Possible research plans associated:

Application Deadline:

25 July 2025 – 23:59 (Europe/Lisbon)

Apply at:

https://apply.uc.pt/IT137-25-279 or https://apply.uc.pt/IT137-25-280

Project details

Participating Institutions in the Project:

- Cork Supply Portugal, S.A.

- IPN – Instituto Pedro Nunes, Associação para a Inovação e Desenvolvimento em Ciência e Tecnologia

- Universidade de Coimbra

Funding/Managing Institution: Agência para o Desenvolvimento e Coesão

Funding Program: PT2030 – MPr-2023-07 – Aviso SIID – I&D Empresarial – Operações em Copromoção – Outros territórios

Execution period: 01/01/2024 to 02/04/2026